Professional auto shops depend on equipment that performs consistently and safely. Among the most critical pieces of equipment are car lifts. These machines allow technicians to access undercarriages, complete repairs efficiently, and maximize floor space in busy workshops. Choosing the right lift means more than simply picking a model that can hold a vehicle’s weight. Reliability comes from a combination of safety, durability, design, and ease of use. Shops that invest in dependable lifts protect their staff, their customers, and their reputation.

Load Capacity and Safety Ratings

Every professional lift must handle the demands of modern vehicles. Weight ratings provide the foundation for trust in a machine’s performance. A lift designed for 7,000 pounds may suffice for sedans and compact SUVs, but heavier vehicles require much higher limits. Commercial shops often look for lifts rated at 10,000 pounds or more to ensure they can service a wide variety of cars and trucks.

Safety certifications matter as much as numbers. Reliable lifts meet industry standards set by organizations such as the Automotive Lift Institute. Certified lifts undergo testing to verify strength, stability, and performance. Using certified equipment gives shop owners confidence and reduces liability in case of accidents.

Construction Quality and Materials

Durability begins with construction. Steel quality, weld strength, and finish all influence how well a lift withstands years of use. Inferior materials bend, rust, or fail under stress, putting both workers and vehicles at risk. Reliable car lifts use heavy-duty steel, corrosion-resistant coatings, and precision engineering to provide consistent performance.

Shops that value long-term savings recognize the importance of strong construction. While cheaper models may cost less upfront, they wear down quickly and require frequent repairs. High-quality lifts remain reliable for decades, providing better value across their lifespan.

Versatility in Design

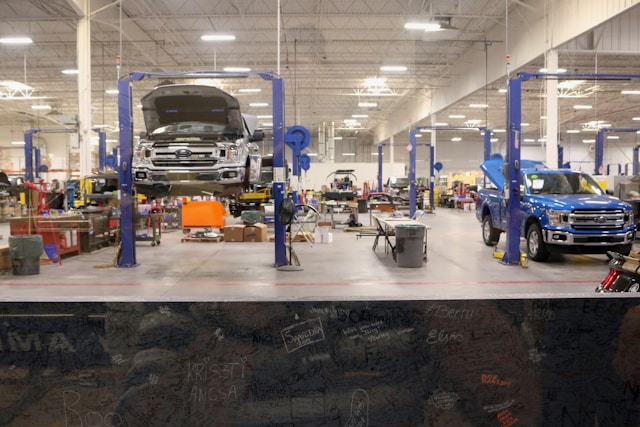

Different repair jobs call for different access points, which is why versatile lift designs make such a difference. Two-post lifts dominate many shops because they provide full access to the undercarriage while taking up minimal floor space. Four-post lifts offer greater stability and serve well for alignment work or long-term storage. Scissor lifts and in-ground lifts provide additional options for specialized tasks.

The ability to handle different vehicles increases efficiency. Shops benefit from lifts with adjustable arms, sliding platforms, and variable height ranges. Investing in versatile equipment allows technicians to work on everything from compact cars to full-size trucks without compromise.

Electrical and Hydraulic Reliability

Car lifts rely on mechanical and electrical systems working in harmony. Hydraulic cylinders provide the lifting force, while pumps and motors ensure smooth operation. Inconsistent pressure, faulty seals, or weak motors compromise reliability. High-quality lifts use industrial-grade hydraulic systems designed for continuous use.

Electrical components must meet strict safety standards. Overheating, poor wiring, or unreliable switches put technicians at risk. Trusted manufacturers integrate safety features such as overload protection and emergency shutoffs to safeguard users. Shops that prioritize electrical and hydraulic reliability minimize downtime and protect workers from accidents.

Long-Term Value and Return on Investment

Reliable car lifts represent significant financial investments, but their long-term value far outweighs their upfront cost. Durable lifts reduce repair expenses, minimize downtime, and increase shop productivity.

Owners who purchase high-quality models avoid frequent replacements and achieve better returns on investment. Working with trusted providers like HeavyLift Direct and similar ones ensures that shops gain access to equipment built for professional demands. These suppliers back their products with warranties, parts availability, and expert guidance, creating confidence in both purchase and performance. Choosing dependable partners transforms equipment buying into a long-term strategy rather than a short-term fix.

Safety Features that Protect Workers

Safety mechanisms define reliable lifts. Automatic locking systems, mechanical safety stops, and pressure relief valves prevent accidents during use. Visual indicators and audible alarms add another layer of security. These features protect both technicians and vehicles during daily operations.

Shops cannot afford to compromise on safety. Equipment that fails to lock properly or lacks backup systems creates unnecessary risk. Prioritizing safety features ensures compliance with industry regulations and provides peace of mind for both managers and employees.

Ergonomic Considerations

Technicians spend long hours working with car lifts, making ergonomics important for health and efficiency. Lifts with adjustable heights reduce strain on workers, while user-friendly controls prevent repetitive stress injuries. Reliable designs prioritize operator comfort alongside performance.

Shops that invest in ergonomically designed lifts see fewer workplace injuries and greater productivity. Workers perform better when equipment supports their physical needs, creating a safer and more positive work environment.

Training and Certification Support

Professional shops benefit from equipment that comes with strong training and certification resources. Reliable manufacturers provide manuals, video tutorials, and on-site training sessions. Certified training programs improve worker confidence and ensure compliance with safety regulations.

Employees who understand proper lift use reduce accidents and extend the life of the equipment. Certification also reassures customers that shops operate at professional standards, which enhances reputation and trust.

Reliable car lifts form the backbone of professional auto shops. Their performance depends on weight capacity, construction quality, safety features, and adaptability. From space efficiency and ergonomic design to hydraulic strength and manufacturer reputation, every detail matters. Shops that invest in dependable lifts secure long-term value, protect workers, and enhance productivity.

Working with trusted providers ensures that equipment meets the demands of modern vehicles and supports future industry changes. With careful selection, car lifts become more than tools; they become assets that define the success of professional automotive businesses.